The focus of this workshop is to achieve a greater understanding of the processes of manufacturing and production of different types of shoe constructions and extensive knowledge of the materials used within each stage of the process.

Intakes

Sep 09, 2024 - Sep 13, 2024

Class schedule

Monday - Friday

Morning 9:00AM - 12:30AM

Afternoon 1:30PM - 5:00PM

Tuition fees

€ 3,000.00

Arsutoria School world-renown training in Boston, MA, U.S.

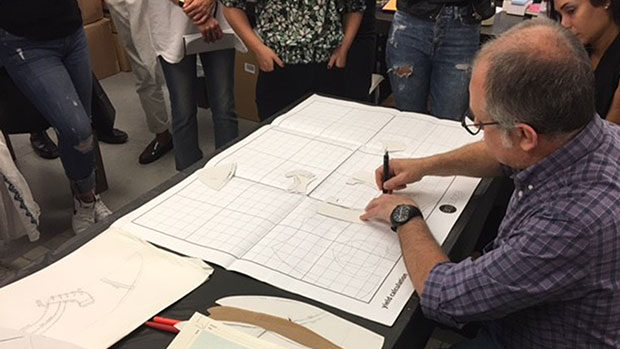

This workshop brings manufacturing, design, and construction expertise of Arsutoria back to the United States. As one of the first international professional development workshops in the US, running for more than 10 years with the proven success of training more than 1000 US professionals, and 75 years of footwear training programs in Italy, we commit to the knowledge advancement and success of each participant.

Fundamentals on shoemaking

The relationship between the human foot and the footwear going through the shoe last. A deep dive into the parameters used in the shoe last development covers production, analysis of length, width, size measurements and size conversion among EU, UK and USA systems. Explanation of upper and lining materials. Focus on interlinings and reinforcements to be used depending on the shoe. Understanding of the process of cutting and upper assembling related to materials and new upper making systems.

Materials and components

Materials for uppers (leathers, fabrics, synthetics, action leather, by-cast) and linings, Middle components (counters, toe boxes, interlinings), Bottom components (mid-soles, outsoles and heels).

Shoe constructions

Overview of production process. Basic upper constructions: board lasted, strobel lasted and tubular moccasin. Basic footwear constructions: cemented outsoles, stitched families (e.g. Blake, stitch-out, Goodyear), vulcanized and injection/direct attach. Alternative/hybrid constructions derived from basic ones and approaches to mix upper and shoe constructions.

Need more information?

Fill out the form, get in touch with our Admissions Team.

No spam, we promise :)